���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

For Bitumen Emulsion Storage

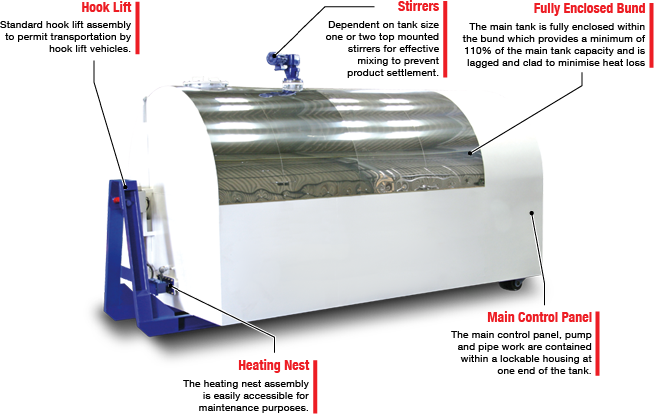

Self contained tanks complete with an integral 110% capacity bund

The units are easily transportable and only require a suitable hard standing and electrical supply for siting.

In response to the need for compliance with increasing environmental standards Parker has developed a range of Self Bunded Tanks for the storage of bitumen emulsions.

With thermostatically controlled electric heating to maintain temperature, an onboard pumping system for loading, offloading and circulation and an agitator for product mixing they provide the complete answer for storage of a wide range of bitumen emulsions including bondcoats and velocity patching materials.

- Self contained units specifically designed for bitumen emulsion storage

- Hook lift, static and mobile units are available

- Fully thermostatically controlled heating

- Built in stirring to prevent product settlement

- Low shear pumping system

Movability

- Each static tank has been designed with transportation in mind, either hook lift, mobile or static tanks are available depending on capacity, and can be moved between sites with ease.

- The hook lift option in particular is fast, efficient and light in operation.

- All tanks are easy to operate and maintain

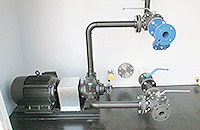

On-board Pump & Valves

- Configured to permit a variety of operations

- Product management through circulation of material

- Fill & load-out utilising either pump

Heating Method

- 415V removable electric elements

- Ceramic heating technology

- Easy to replace and maintain

Tank Fittings

- Top mounted agitator

- Hydrostatic contents measurement

- Electric bund alarm detection

Controls

- Easy and simple to operate

- Thermostatically controlled heating

- Digital temperature controller

- 24/7 time clock with back up power

- Contents level audio and visual alarms

| |

Self Bunded Tanks |

| Description |

Units |

Hook Lift |

Static |

Mobile |

| Tank Configurations |

| Capacity |

18,000 |

Litres |

• |

- |

- |

| 20,000 |

Litres |

- |

• |

• |

| 25,000 |

Litres |

- |

- |

• |

| 30,000 |

Litres |

- |

• |

• |

| 35,000 |

Litres |

- |

- |

• |

| 40,000 |

Litres |

- |

• |

• |

| 50,000 |

Litres |

- |

• |

- |

| 60,000 |

Litres |

- |

• |

- |

| Heating |

| Electric Ceramic Heating Elements |

- |

• |

• |

• |

| Thermostatic Control |

- |

• |

• |

• |

| High Temperature Limit Switch |

- |

• |

• |

• |

| Pump |

| External Sliding Vane Type |

- |

• |

• |

• |

| Flow Rate |

Litres / Hr |

30,360 |

30,360 |

30,360 |

| Motor Size |

kW |

7.5 |

7.5 |

7.5 |

| Agitators |

| 18,000 to 40,000 Litres |

- |

1 |

1 |

1 |

| 50,000 to 60,000 Litres |

- |

- |

2 |

- |

| Running Gear |

| 20,000 to 30,000 Litres |

Axles |

- |

- |

1 |

| 35,000 to 40,000 Litres |

Axles |

- |

- |

2 |

| Electrical Supply |

| 400 Volt, 3 Phase, 50 Hz |

- |

• |

• |

• |

• = Standard Equipment

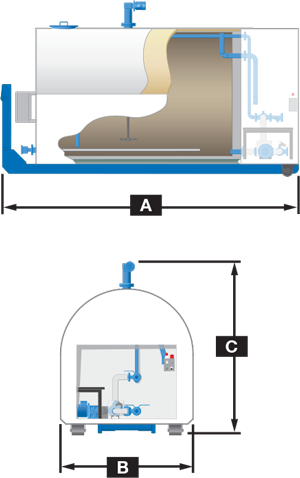

| 18,000L Self Bunded Tank |

| Dimensions |

Units |

Hook Lift |

| Length |

A |

m |

5.97 |

| inches |

235” |

| Width |

B |

m |

2.65 |

| inches |

104 ½” |

| Height |

C |

m |

3.48 |

| inches |

137” |

Note:Illustration and dimensions shown for the 18,000L capacity hook-lift model.

Русский (RU)

Русский (RU)  English (UK)

English (UK)