Vertical Bitumen Storage

Highly efficient and economical vertical bitumen storage tanks

The Parker High Efficiency Vertical Bitumen tanks have been designed and developed to be used on sites where space is at a premium.

Energy costs are high and trends would suggest a continued rise in the longer term. Within the quarrying industry bitumen storage is a significant contributor to energy usage but due to its secondary nature in the day to day operation of a coating plant it may not always be given the attention it deserves. Therefore when purchasing a new bitumen tank thermal efficiency should be an important consideration in the decision making process.

A new Parker High Efficiency Vertical Bitumen Storage Tank can provide significant energy savings and reduce an operation’s carbon footprint. There is an ever increasing focus on the environmental and safety issues surrounding bitumen spillage. Parker ensures its tanks conform to industry best practice guidelines regarding safe handling of bitumen, including safe working capacity, available ullage, accurate contents gauges and high level alarms all of which greatly reduce the risk of spills occurring.

- Conforms to RBA best practice relating to safety

- Range of heating options available

- Capacities from 30,000 - 200,000 liters

- Accurate continuous level indication

- 300mm thick high efficiency insulation

- Temperature Indication monitoring

- Independent ultimate high level alarm

- Optional top mounted tank agitator

- Traffic light fill system

- Easy to operate & requires minimal maintenance

Features

Construction

Fabricated cylindrical tank. Submerged ARC weld inside & out. Compliant to current RBA recommendations. Carbon steel BSEN standard.

Termal Insulation

300mm high density thermal wool insulation. Staggered joints for greater heat retention. 75mm more Insulation as standard.

Efficient Foil Blanket

Greater thermal resistance. Improved energy saving. Weather-proof material ensures added protection against the elements.

Heating Technology

Removable ceramic electric heating elements. Increased heat transfer. Easy to replace and maintain. Totally enclosed heater bank.

Tank Fittings

Guide wave radar level indicator. High level/low level audio & visual alarms. Optional agitators for PMB storage. Optional access ladders.

Pump & Pipe Work

Bitumen pump & valves. Bespoke pipe work installations. Fill point traffic light indicators. Optional telemetry systems.

Minimal Heat Loss

Thermographic image showing minimal heat loss.

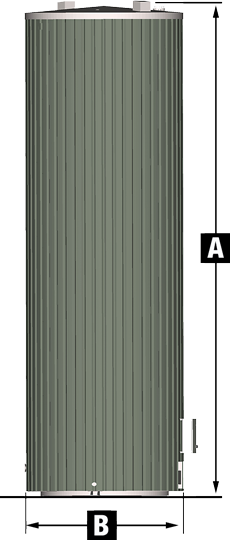

Specifications

| Units | High Efficiency Vertical Bitumen Storage Tanks | ||||||||||

| Safe Working Capacity* | Tonnes | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| Dimensions | |||||||||||

| Overall Height | A | m | 6.52 | 8.22 | 9.71 | 11.19 | 12.90 | 14.61 | 13.25 | 14.62 | |

| inches | 256 3/4” | 323 3/4” | 382 1/4” | 440 1/2” | 508” | 575 1/4” | 521 3/4” | 575 1/2” | |||

| Overall Diameter | B | m | 3.61 | 3.61 | 3.61 | 3.61 | 3.61 | 3.61 | 3.97 | 3.97 | |

| inches | 142 1/4” | 142 1/4” | 142 1/4” | 142 1/4” | 142 1/4” | 142 1/4” | 156 1/4” | 156 1/4” | |||

| Heating System | |||||||||||

| Total Load | kW | 45 | 45 | 45 | 45 | 45 | 60 | 60 | 60 | ||

| Switching Stages | Unit | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Elements | Unit | 9 | 9 | 9 | 9 | 9 | 12 | 12 | 12 | ||

| Siting Details1 | |||||||||||

| Base Diameter | m | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.35 | 3.35 | ||

| inches | 118 1/4” | 118 1/4” | 118 1/4” | 118 1/4” | 118 1/4” | 118 1/4” | 132” | 132” | |||

| Other Information | |||||||||||

| Lagging Depth | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | ||

| inches | 12” | 12” | 12” | 12” | 12” | 12” | 12” | 12” | |||

| Complies With RBA Guidelines | - | • | • | • | • | • | • | • | • | ||

Русский (RU)

Русский (RU)  English (UK)

English (UK)