Conveyor Systems

& Bulk Handling Solutions

Conveyor Types

Complete Systems

With experience in the design, manufacture & installation of small, medium & large turnkey schemes, Universal Conveyors is able to supply complete handling systems. Complete systems may incorporate any combination of conveyors, bins, structures & associated equipment to provide a fully integrated handling system.

Troughed Belt Conveyors

The Universal Conveyors range of Troughed belt conveyors are individually designed to suit a customer's specific requirements. Standard components are incorporated throughout the range, enabing future modifications if required. Any size of troughed belt conveyor can be manufactured, whether it is ground, aerial or angled. Options such as walkways, trip wires & covered conveyors can be supplied throughout the troughed belt range.

Mobile Troughed Belt Conveyors

The robust construction of our Mobile Troughed Belt Conveyors & the ease with which they can be installed allow the mobile range to compliment both small or large scale operations. Universal Conveyors Ltd manufacture a standard range of 4000 Series & 5000 Series conveyors incorporating 500mm, 650mm, 800mm & 1000mm belt widths available as standard. Radial options are available for kidney shaped stockpiling.

Field Conveyors

Field conveyors are an immediate conveying solution for the most rugged of environments. Designed for rapid & easy installation a field conveyor can be installed in a fraction of the time it would take to install a conventional conveyor of a similar size. The conveyor sets are available with a fixed troughing angle of 30° or 35° or with variable spring laoaded troughing angles. The sets are interchangable eith other variable trough structures of a similar design.

Radial Troughed Belt Conveyors

Radial Troughed Conveyors can be used individually or incorporated in large handling systems. The Radial Conveyor is anchored at the tail end & enables local radial stockpiling. Radial Conveyors are not confined to being ground mounted & can be incorporated in aerial structures. Large conveyors are available according to specific requirements.

Stockpile & Reclaim Conveyors

Stockpile & Reclaim conveyors are vital equipment in the material handling process, whether in large turnkey systems or when operated independently. The Stockpile Conveyor is often inclined to allow maximum stockpiling. Reclaim Conveyors are integral to the stockpile & allow material to be transported from the main pile. Both types of conveyor are available in mobile & static form & can be incorporated into turnkey systems or operated as standalone units.

Trippers

Travelling throw-off Trippers can be incorporated into a variety of conveyor systems. Throw-off Trippers divert material from the main conveyor & consequently stop any discharging from over the conveyor drive pulley. This is often necessary on long stockpile conveyors that feed storage bins. Trippers are either hand or electrically powered. Operator platforms can be included on moveable trippers. Gated chutes or cantilevered conveyors to extend the stockpiles can be optionally fitted.

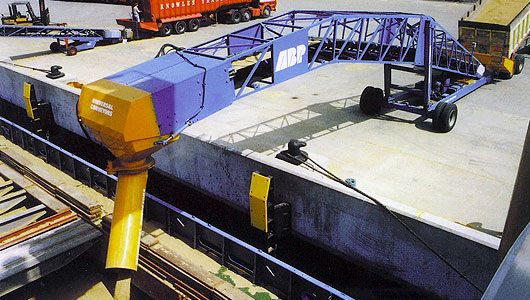

Ship Loaders

Designed to compliment modern day shiploading, Shiploading Conveyors enable the rapid loading of materials direct from the land transport. Available in static form or as a mobile unit, the Shiploading Conveyor aids the efficiency of dockside material handling. All Shiploading Conveyors are individually designed to suit specific applications & handling capacities

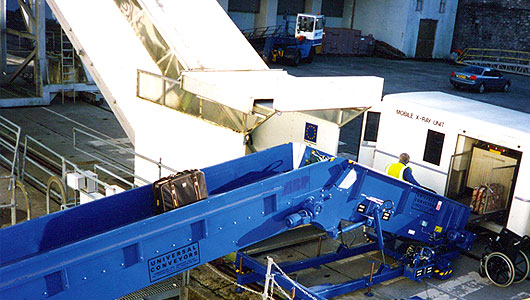

Telescopic Conveyors

The Universal Conveyors range of Telescopic, flat belt conveyors can be operated as stand-alone units or can be incorporated as part of larger unit handling systems. The Telescopic Conveyor is suitable for handling bulk objects or small packages. The Telescopic Conveyor provides the operator with the ability to adjust the unit's height & length as & when required. The unit's flexibility ensures that the telescopic conveyor can be incorporated into applications such as cargo/freight handling.

Flat Belt Conveyors

Universal Conveyors Flat Belt Conveyors are available as standard units or may be designed to suit specific applications. Individual conveyors can be arranged as inclined, horizontal or as a combination & can be incorporated to form part of a complete handling system. Fixed or variable speed units are available.

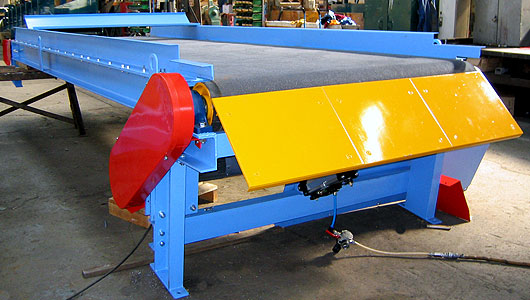

Picking Stations

The Universal Conveyors Picking-Station range has been designed to allow the manual grading of recycled products. Waste materials are transported through the picking section on a horizontal conveyor, from which material is sorted by hand. Graded waste is removed from the picking belt & then channeled through chutes into skips or bays located beneath the picking station.

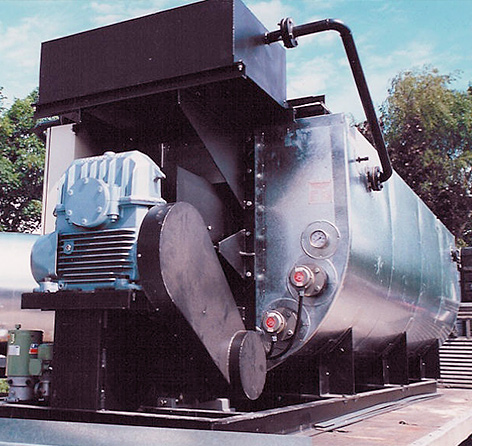

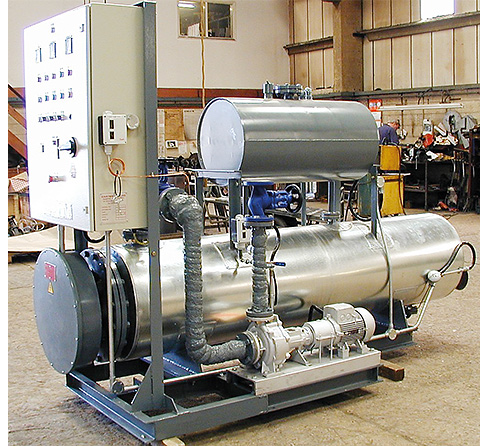

RAP Feeder Systems

RAP Feed Systems can be designed for inclusion within new plants or for retro-fitting into existing asphalt plants and can include features such as feed system belt conveyors and elevators for RAP transfer, or self-sealing feed chute systems for instruction of RAP materials into a mixer and/ or elvator.

Русский (RU)

Русский (RU)  English (UK)

English (UK)