���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������

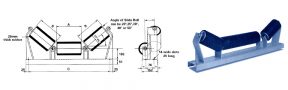

Standard Rollers

Universal Conveyors Idlers are manufactured from accurately cut steel tubes with fully welded, pressed steel bearing housings at each end, pre-assembled with high quality, deep grroved bearings and flame retardent multi-lip seals.

Both the bearing and seal housings are packed with Fuchs Remolit Aqua 2 water resistant grease to lubricate and protect from the ingress of harmfull material.

Using the latest developments in modern machinery all Universal Conveyors rollers are manufactured to the highest standard meeting BS and ISO recommendations.

Quality control checks are made to ensure that rollers are well within the tolerances set by both our own and relevant British Standards.

A full range of conveyor drums are also manufactured & full technical support is provided.

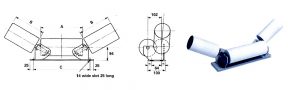

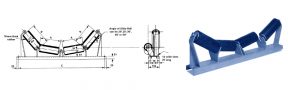

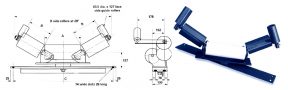

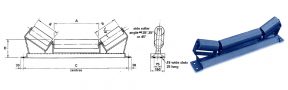

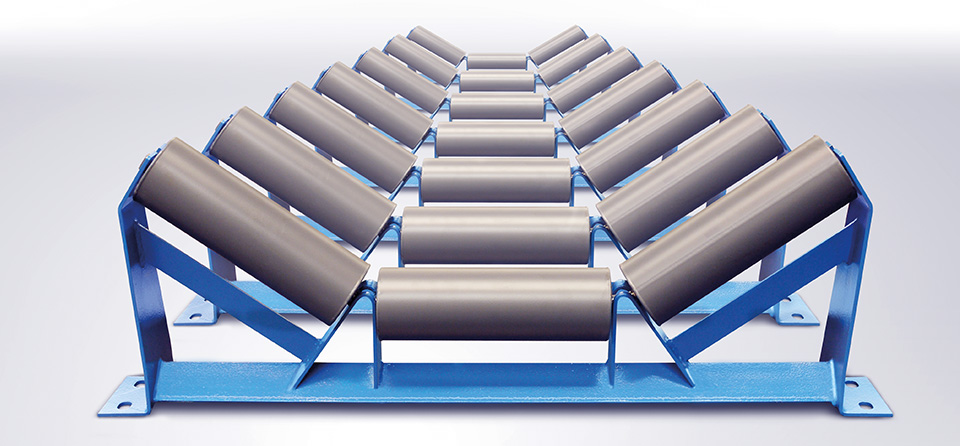

Multitrough conveyor idlers

Multitrough Idlers Incorporating adjustable wing rollers which may be set at increments, from 20° to 60°, enabling the belt to run at either conventional or deep troughing angles.

The rollers can be easily adjusted & the angle can be varied adjacent to the head & tail drums, to ensure smooth transition from trough to flat conditions without undue belt stress.

All dimensions comply to BS 2890.

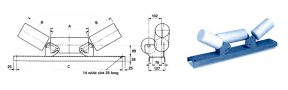

3 Roll Transome Type

Belt Width Range: 300mm to 1000mm

Belt Width

(mm) |

Dimensions |

Transome

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

| 300 - 350 |

152 |

127 |

584 |

12LT |

AD 12T |

D6CRXX |

D5SRXX |

AE 12T |

E6CR25 |

E5SR25 |

| 400 |

152 |

178 |

635 |

16LT |

AD 16T |

D6CRXX |

D7SRXX |

AE 16T |

E6CR25 |

E5SR25 |

| 450 |

203 |

178 |

686 |

18LT |

AD 18T |

D8CRXX |

D7SRXX |

AE 18T |

E8CR25 |

E7SR25 |

| 500 |

203 |

203 |

737 |

20LT |

AD 20T |

D8CRXX |

D8SRXX |

AE 20T |

E8CR25 |

E8SR25 |

| 600 |

305 |

203 |

838 |

24LT |

AD 24T |

D12CRXX |

D8SRXX |

AE 24T |

E12CR25 |

E8SR25 |

| 650 |

356 |

203 |

889 |

26LT |

AD 26T |

D14CRXX |

D8SRXX |

AE 26T |

E12CR25 |

E8SR25 |

| 750 |

356 |

254 |

991 |

30LT |

AD 30T |

D14CRXX |

D10SRXX |

AE 30T |

E14CR25 |

E10SR25 |

| 800 |

406 |

254 |

1041 |

32LT |

AD 32T |

D16CRXX |

D10SRXX |

AE 32T |

E14CR25 |

E10SR25 |

| 900 |

508 |

254 |

1143 |

36LT |

AD 36T |

D20CRXX |

D10SRXX |

AE 36T |

E20CR25 |

E10SR25 |

| 1000 |

558 |

279 |

1240 |

40LT |

AD 40T |

D22CRXX |

D11SRXX |

AE 40T |

E22CR25 |

E11SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

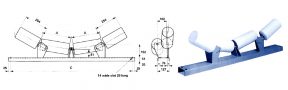

3 Roll Baseplate Type

Belt Width Range: 300mm to 1000mm

Belt Width

(mm) |

Dimensions |

Baseplate

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Baseplate Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

Baseplate Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

| 300 - 350 |

152 |

127 |

254 |

12B |

AD 12B |

D6CRXX |

D5SRXX |

AE 12B |

E6CR25 |

E5SR25 |

| 400 |

152 |

178 |

305 |

16B |

AD 16B |

D6CRXX |

D7SRXX |

AE 16B |

E6CR25 |

E7SR25 |

| 450 |

203 |

178 |

305 |

18B |

AD 18B |

D8CRXX |

D7SRXX |

AE 18B |

E8CR25 |

E7SR25 |

| 500 |

203 |

203 |

330 |

20B |

AD 20B |

D8CRXX |

D8SRXX |

AE 20B |

E8CR25 |

E8SR25 |

| 600 |

305 |

203 |

406 |

24B |

AD 24B |

D12CRXX |

D8SRXX |

AE 24B |

E12CR25 |

E8SR25 |

| 650 |

356 |

203 |

483 |

26B |

AD 26B |

D14CRXX |

D8SRXX |

AE 26B |

E14CR25 |

E8SR25 |

| 750 |

356 |

254 |

483 |

30B |

AD 30B |

D14CRXX |

D10SRXX |

AE 30B |

E14CR25 |

E10SR25 |

| 800 |

406 |

254 |

533 |

32B |

AD 32B |

D16CRXX |

D10SRXX |

AE 32B |

E16CR25 |

E10SR25 |

| 900 |

508 |

254 |

635 |

36B |

AD 36B |

D16CRXX |

D10SRXX |

AE 36B |

E20CR25 |

E10SR25 |

| 1000 |

558 |

279 |

685 |

40B |

AD 40B |

D18CRXX |

D11SRXX |

AE 40B |

E22CR25 |

E11SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

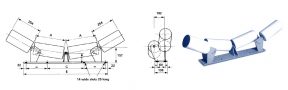

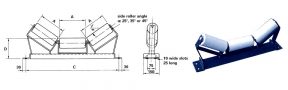

4 Roll Transome Type

Belt Width Range: 1000mm to 1500mm

Belt Width

(mm) |

Dimensions |

Transome

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

C (mm) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

| 1000 - 1500 |

305 |

1295 |

42LT |

AD 42T |

D12CRXX |

D10SRXX |

AE 42T |

E12CR25 |

E10SR25 |

| 1200 |

406 |

1448 |

48LT |

AD 48T |

D16CRXX |

D10SRXX |

AE 48T |

E16CR25 |

E10SR25 |

| 1400 |

457 |

1600 |

54LT |

AD 54T |

D18CRXX |

D10SRXX |

AE 54T |

E18CR25 |

E10SR25 |

| 1500 |

559 |

1753 |

60LT |

AD 60T |

D22CRXX |

D10SRXX |

AE 60T |

E22CR25 |

E10SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

4 Roll Baseplate Type

Belt Width Range: 1000mm to 1500mm

Belt Width

(mm) |

Dimensions |

Baseplate

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

C (mm) |

E (mm) |

Baseplate Sets

(Ref No.) |

Centre Rollers

(Ref No.) |

Side Roller

(Ref No.) |

Baseplate Sets

(Ref No.) |

Centre Rollers

(Ref No.) |

Side Roller

(Ref No.) |

| 1000 - 1500 |

305 |

367 |

813 |

42B |

AD 42B |

D12CRXX |

D10SRXX |

AE 42B |

E12CR25 |

E10SR25 |

| 1200 |

406 |

545 |

1016 |

48B |

AD 48B |

D16CRXX |

D10SRXX |

AE 48B |

E16CR25 |

E10SR25 |

| 1400 |

457 |

697 |

1118 |

54B |

AD 54B |

D18CRXX |

D10SRXX |

AE 54B |

E18CR25 |

E10SR25 |

| 1500 |

559 |

849 |

1321 |

60B |

AD 60B |

D22CRXX |

D10SRXX |

AE 60B |

E22CR25 |

E10SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

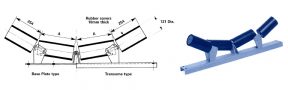

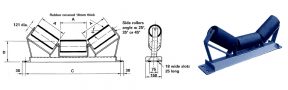

3 Roll Rubber Covered Troughing Idlers

Belt Width Range: 400mm to 1000mm

Belt Width

(mm) |

Dimensions |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

3 Roll Rubber Covered

Transome Troughing Idlers |

3 Roll Rubber Covered

Baseplate Troughing Idlers |

| A (mm) |

B (mm) |

Transome Type / Sets

(Ref No.) |

Transome

(Ref No.) |

Baseplate Type / Sets

(Ref No.) |

Baseplate

(Ref No.) |

| 400 |

152 |

178 |

D6CRXXRC |

D7SRXXRC |

RT 16T |

16 LT |

RT 16B |

16B |

| 450 |

203 |

178 |

D8CRXXRC |

D7SRXXRC |

RT 18T |

18 LT |

RT 18B |

18B |

| 500 |

203 |

203 |

D8CRXXRC |

D8SRXXRC |

RT 20T |

20 LT |

RT 20B |

20B |

| 600 |

305 |

203 |

D12CRXXRC |

D8SRXXRC |

RT 24T |

24 LT |

RT 24B |

24B |

| 650 |

356 |

203 |

D14CRXXRC |

D8SRXXRC |

RT 26T |

26 LT |

RT 26B |

26B |

| 750 |

356 |

254 |

D14CRXXRC |

D10SRXXRC |

RT 30T |

30 LT |

RT 30B |

30B |

| 800 |

406 |

254 |

D16CRXXRC |

D10SRXXRC |

RT 32T |

32 LT |

RT 32B |

32B |

| 900 |

508 |

254 |

D20CRXXRC |

D10SRXXRC |

RT 36T |

36 LT |

RT 36B |

36B |

| 1000 |

558 |

279 |

D22CRXXRC |

D11SRXXRC |

RT 40T |

40 LT |

RT 40B |

40B |

XX = Spindle diameter

1. 122Ø Rubber covered rollers can be supplied with 20 or 25Ø spindles

4 Roll Rubber Covered Troughing Sets

Belt Width Range: 1000mm to 1500mm

Belt Width

(mm) |

Dimensions

A (mm) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

4 Roll Rubber Covered

Transome Troughing Idlers |

4 Roll Rubber Covered

Baseplate Troughing Idlers |

Transome Type / Sets

(Ref No.) |

Transome

(Ref No.) |

Baseplate Type / Sets

(Ref. No.) |

Baseplate

(Ref No.) |

| 1000 - 1050 |

305 |

D12CRXXRC |

D10SRXXRC |

RT 42T |

42 LT |

RT 42B |

42B |

| 1200 |

406 |

D16CRXXRC |

D10SRXXRC |

RT 48T |

48 LT |

RT 48B |

48B |

| 1400 |

457 |

D18CRXXRC |

D10SRXXRC |

RT 54T |

54 LT |

RT 54B |

54B |

| 1500 |

559 |

D22CRXXRC |

D10SRXXRC |

RT 60T |

60 LT |

RT 60B |

60B |

XX = Spindle diameter

1. 122Ø Rubber covered rollers can be supplied with 20 or 25Ø spindles

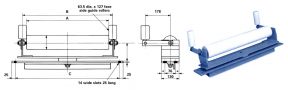

3 Roll Impact Troughing Sets

Belt Width Range: 600mm to 1000mm

Belt Width

(mm) |

Dimensions |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets (Ref No.) |

Centre Roller (Ref No.) |

Side Roller (Ref No.) |

Transome (Ref No.) |

| 600 |

235 |

235 |

838 |

HD 24Π|

HD9.25CR25 |

HD9.25SR25 |

24LTHDΠ|

| 650 |

311 |

235 |

889 |

HD 26Π|

HD12.25CR25 |

HD9.25SR25 |

26LTHDΠ|

| 750 |

384 |

235 |

991 |

HD 30Π|

HD15.125CR25 |

HD9.25SR25 |

30LTHDΠ|

| 800 |

460 |

235 |

1041 |

HD 32Π|

HD18.12CR25 |

HD9.25SR25 |

32LTHDΠ|

| 900 |

533 |

235 |

1143 |

HD 36Π|

HD21.00CR25 |

HD9.25SR25 |

36LTHDΠ|

| 1000 |

610 |

235 |

1240 |

HD 40Π|

HD24.00CR25 |

HD9.25SR25 |

40LTHDΠ|

Π= Angle of side roller (fixed at manufacture)

4 Roll Impact Troughing Sets

Belt Width Range: 1000mm to 1500mm

|

Belt Width

(mm)

|

Dimensions |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets Ref No. |

Centre Roller (Ref No.) |

Side Roller (Ref No.) |

Transome (Ref No.) |

| 1000 |

311 |

311 |

1295 |

HD 42Π|

HD12.25CR-425 |

HD12.25SR-425 |

42LTHDΠ|

| 1200 |

384 |

311 |

1448 |

HD 48Π|

HD15.12CR-425 |

HD12.25SR-425 |

48LTHDΠ|

| 1400 |

384 |

384 |

1600 |

HD 54Π|

HD15.12CR-425 |

HD15.12SR-425 |

54LTHDΠ|

| 1500 |

460 |

384 |

1753 |

HD 60Π|

HD18.12CR-425 |

HD15.12SR-425 |

60LTHDΠ|

Π= Angle of side roller (fixed at manufacture)

3 Roll Transome Type Picking Idler Sets

Belt Width Range: 750mm to 1500mm

Belt Width

(mm) |

Dimensions |

Transome

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

Transome Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

| 750 |

457 |

203 |

991 |

30LTP |

AD 30TP |

D18CRXX |

D8SRXX |

AE 30TP |

E18CR25 |

E8SR25 |

| 800 |

508 |

203 |

1041 |

32LTP |

AD 32TP |

D20CRXX |

D8SRXX |

AE 32TP |

E20CR25 |

E8SR25 |

| 900 |

610 |

203 |

1143 |

36LTP |

AD 36TP |

D24CRXX |

D8SRXX |

AE 36 TP |

E24CR25 |

E8SR25 |

| 1000 |

711 |

203 |

1240 |

40LTP |

AD 40TP |

D28CRXX |

D8SRXX |

AE 40TP |

E28CR25 |

E8SR25 |

| 1050 |

762 |

203 |

1295 |

42LTP |

AD 42TP |

D30CRXX |

D8SRXX |

AE 42TP |

E30CR25 |

E8SR25 |

| 1200 |

914 |

203 |

1448 |

48LTP |

AD 48TP |

D36CRXX |

D8SRXX |

AE 48TP |

E36CR25 |

E8SR25 |

| 1400 |

1067 |

203 |

1600 |

54LTP |

AD 54TP |

D42CRXX |

D8SRXX |

AE 54TP |

E42CR25 |

E8SR25 |

| 1500 |

1219 |

203 |

1753 |

60LTP |

AD 60TP |

D48CRXX |

D8SRXX |

AE 60TP |

E48CR25 |

E8SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

3. Transomes can also be supplied with 122mm dia. rubber covered rollers

3 Roll Baseplate Type Picking Idler Sets

Belt Width Range: 750mm to 1500mm

Belt Width

(mm) |

Dimensions |

Baseplate

(Ref No.) |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Baseplate Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

Baseplate Sets

(Ref No.) |

Centre Roller

(Ref No.) |

Side Roller

(Ref No.) |

| 750 |

457 |

203 |

584 |

30 BP |

AD 30BP |

D18CRXX |

D8SRXX |

AE 30BP |

E18CR25 |

E8SR25 |

| 800 |

508 |

203 |

635 |

32 BP |

AD 32BP |

D20CRXX |

D8SRXX |

AE 32BP |

E20CR25 |

E8SR25 |

| 900 |

610 |

203 |

737 |

36 BP |

AD 36BP |

D24CRXX |

D8SRXX |

AE 36BP |

E24CR25 |

E8SR25 |

| 1000 |

711 |

203 |

838 |

40 BP |

AD 40BP |

D28CRXX |

D8SRXX |

AE 40BP |

E28CR25 |

E8SR25 |

| 1050 |

762 |

203 |

889 |

42 BP |

AD 42BP |

D30CRXX |

D8SRXX |

AE 42BP |

E30CR25 |

E8SR25 |

| 1200 |

914 |

203 |

1041 |

48 BP |

AD 48BP |

D36CRXX |

D8SRXX |

AE 48BP |

E36CR25 |

E8SR25 |

| 1400 |

1067 |

203 |

1194 |

54 BP |

AD 54BP |

D42CRXX |

D8SRXX |

AE 54BP |

E42CR25 |

E8SR25 |

| 1500 |

1219 |

203 |

1346 |

60 BP |

AD 60BP |

D48CRXX |

D8SRXX |

AE 60BP |

E48CR25 |

E8SR25 |

XX = Spindle diameter

1. 102Ø Rollers can be supplied with 20 or 25Ø spindles

2. 127Ø Rollers can only be supplied with 25Ø spindles

3. Transomes can also be supplied with 122mm dia. rubber covered rollers

Self Aligning Idler Sets

Belt Width Range: 350mm to 1000mm

|

Belt Width

(mm)

|

Dimensions |

102mm Diameter Troughing Idlers |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets

(Ref No.) |

Centre Rollers

(Ref No.) |

Side Rollers

(Ref No.) |

Transome Sets

(Ref No.) |

Centre Rollers

(Ref No.) |

Side Rollers

(Ref No.) |

| 300 - 350 |

152 |

127 |

584 |

AD 12S |

D6SRXX |

D5SR25SE |

- |

- |

- |

| 400 |

152 |

178 |

635 |

AD 16S |

D6SRXX |

D7SR25SE |

AE 16S |

E6CR25 |

E7SR25SE |

| 450 |

203 |

178 |

686 |

AD 18S |

D8SRXX |

D7SR25SE |

AE 18S |

E8CR25 |

E7SR25SE |

| 500 |

203 |

203 |

737 |

AD 20S |

D8SRXX |

D8SR25SE |

AE 20S |

E8CR25 |

E8SR25SE |

| 600 |

305 |

203 |

838 |

AD 24S |

D12SRXX |

D8SR25SE |

AE 24S |

E12CR25 |

E8SR25SE |

| 650 |

356 |

203 |

889 |

AD 26S |

D14SRXX |

D8SR25SE |

AE 26S |

E14CR25 |

E8SR25SE |

| 750 |

356 |

254 |

991 |

AD 30S |

D14SRXX |

D10SR25SE |

AE 30S |

E14CR25 |

E10SR25SE |

| 800 |

406 |

254 |

1041 |

AD 32S |

D16SRXX |

D10SR25SE |

AE 32S |

E16CR25 |

E10SR25SE |

| 900 |

508 |

254 |

1143 |

AD 36S |

D20SRXX |

D10SR25SE |

AE 36S |

E20CR25 |

E10SR25SE |

| 1000 |

558 |

279 |

1240 |

AD 40S |

D22SRXX |

D11SR25SE |

AE 40S |

E22CR25 |

E11SR25SE |

XX = Spindle diameter

1. 102Ø Centre rollers can be supplied with 20 or 25Ø spindles

2. 102Ø Side and all 127Ø rollers can only be supplied with 25Ø spindles

3. 63.5 dia. Side guide roller ref = BSGR25M

4. Side guide roller brackets (pair) ref = SA-BRKT

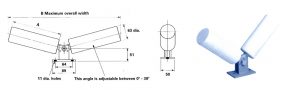

2 Roll Troughing Idler Sets

Belt Width Range: 250mm to 400mm

Belt Width

(mm) |

Dimensions |

63.5mm Diameter Adjustable Angle Troughing Iders |

| A (mm) |

B (mm) |

Transome Sets

(Ref No.) |

Rollers

(Ref No.) |

2 Roll Bracket

(Ref No.) |

| 250 |

132 |

311 |

B 10B |

B 10B |

2-ROLL-BRKT |

| 300 |

152 |

362 |

B 12B |

B 12B |

2-ROLL-BRKT |

| 350 |

178 |

413 |

B 14B |

B 14B |

2-ROLL-BRKT |

| 400 |

203 |

464 |

B 16B |

B 16B |

2-ROLL-BRKT |

Self Aligning Return Idlers

Belt Width Range: 350mm to 1000mm

Belt Width

(mm) |

Dimensions |

102mm Diameter Self Aligning Return Idlers |

| A (mm) |

B (mm) |

C (mm) |

Transome Sets

Ref No. |

Return Roller

(Ref No.) |

Transome

(Ref No.) |

| 300 - 350 |

432 |

546 |

584 |

DP 12S |

DP12XX |

12SA-R |

| 400 |

483 |

597 |

635 |

DP 16S |

DP16XX |

16SA-R |

| 450 |

533 |

648 |

686 |

DP 18S |

DP18XX |

18SA-R |

| 500 |

584 |

699 |

737 |

DP 20S |

DP20XX |

20SA-R |

| 600 |

686 |

800 |

838 |

DP 24S |

DP24XX |

24SA-R |

| 650 |

737 |

851 |

889 |

DP 26S |

DP26XX |

26SA-R |

| 750 |

838 |

953 |

991 |

DP 30S |

DP30XX |

30SA-R |

| 800 |

889 |

1003 |

1041 |

DP 32S |

DP32XX |

32SA-R |

| 900 |

991 |

1105 |

1143 |

DP 36S |

DP36XX |

36SA-R |

| 1000 |

1092 |

1205 |

1240 |

DP 40S |

DP40XX |

40SA-R |

XX = Spindle diameter

1. 102Ø Return rollers can be supplied with 20 or 25Ø spindles

2. 63.5 dia. Side guide roller ref = BSGR25M

3. Side guide roller brackets (pair) ref = SA-BRKT

Return Idlers

Belt Width Range: 250mm to 1500mm

Belt Width

(mm) |

Dimensions A (mm) |

63mm Dia.

(Ref No.) |

76mm Dia.

(Ref No.) |

102mm Dia.

(Ref No.) |

127mm Dia.

(Ref No.) |

Rubber Covered Type

121mm Dia. (Ref No.) |

Imapct Type

127mm Dia. (Ref No.) |

| 250 |

330 |

BP 10XX |

- |

- |

- |

- |

- |

| 300 |

432 |

BP 12XX |

CP 12XX |

DP 12XX |

EP 12H25 |

RP 12H25 |

- |

| 350 |

432 |

BP 12XX |

CP 12XX |

DP 12XX |

EP 12H25 |

RP 12H25 |

- |

| 400 |

483 |

BP 16XX |

CP 16XX |

DP 16XX |

EP 16H25 |

RP 16H25 |

- |

| 450 |

533 |

BP 18XX |

CP 18XX |

DP 18XX |

EP 18H25 |

RP 18H25 |

- |

| 500 |

584 |

BP 20XX |

CP 20XX |

DP 20XX |

EP 20H25 |

RP 20H25 |

- |

| 600 |

686 |

BP 24XX |

CP 24XX |

DP 24XX |

EP 24H25 |

RP 24H25 |

HP 2425 |

| 650 |

737 |

BP 26XX |

CP 26XX |

DP 26XX |

EP 26H25 |

RP 26H25 |

HP 2625 |

| 750 |

838 |

BP 30XX |

CP 30XX |

DP 30XX |

EP 30H25 |

RP 30H25 |

HP 3025 |

| 800 |

889 |

BP 32XX |

CP 32XX |

DP 32XX |

EP 32H25 |

RP 32H25 |

HP 3225 |

| 900 |

991 |

BP 36XX |

CP 36XX |

DP 36XX |

EP 36H25 |

RP 36H25 |

HP 3625 |

| 1000 |

1092 |

BP 40XX |

CP 40XX |

DP 40XX |

EP 40H25 |

RP 40H25 |

HP 4025 |

| 1050 |

1143 |

BP 42XX |

CP 42XX |

DP 42XX |

EP 42H25 |

RP 42H25 |

HP 4225 |

| 1200 |

1295 |

BP 48XX |

CP 48XX |

DP 48XX |

EP 48H25 |

RP 48H25 |

HP 4825 |

| 1400 |

1448 |

BP 5425 |

CP 54XX |

DP 54XX |

EP 54H25 |

RP 54H25 |

HP 5425 |

| 1500 |

1600 |

BP 6025 |

CP 60XX |

DP 60XX |

EP 60H25 |

RP 60H25 |

HP 6025 |

XX = Spindle diameter

1. 63.5, 76 & 102Ø Rollers upto and including 1200 wide can be supplied with 20 or 25Ø spindles

Disc Return Idlers

Belt Width Range: 300mm to 1500mm

Belt Width

(mm) |

Dimensions |

152mm Dia. Discs (Ref No.) |

191mm Dia. Discs (Ref. No.) |

| A (mm) |

B (No. of Pitches) |

C (mm) |

| 300 |

432 |

2 |

114 |

6RD BP12XX |

7RD CP12XX |

| 350 |

432 |

2 |

114 |

6RD BP12XX |

7RD CP12XX |

| 400 |

483 |

2 |

114 |

6RD BP16XX |

7RD CP16XX |

| 450 |

533 |

2 |

114 |

6RD BP18XX |

7RD CP18XX |

| 500 |

584 |

3 |

114 |

6RD BP20XX |

7RD CP20XX |

| 600 |

686 |

3 |

114 |

6RD BP24XX |

7RD CP24XX |

| 650 |

737 |

4 |

114 |

6RD BP26XX |

7RD CP26XX |

| 750 |

838 |

4 |

114 |

6RD BP30XX |

7RD CP30XX |

| 800 |

889 |

4 |

114 |

6RD BP32XX |

7RD CP32XX |

| 900 |

991 |

5 |

114 |

6RD BP36XX |

7RD CP36XX |

| 1000 |

1092 |

6 |

114 |

6RD BP40XX |

7RD CP40XX |

| 1050 |

1143 |

6 |

114 |

6RD BP42XX |

7RD CP42XX |

| 1200 |

1295 |

7 |

114 |

6RD BP48XX |

7RD CP48XX |

| 1400 |

1448 |

8 |

114 |

6RD BP54XX |

7RD CP54XX |

| 1500 |

1600 |

9 |

114 |

6RD BP60XX |

7RD CP60XX |

XX = Spindle diameter

1. Disc return rollers upto and including 1200 wide can be supplied with 20 or 25Ø spindles

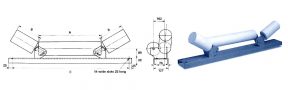

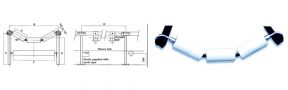

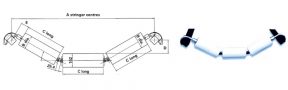

Unitrough & Intertrough Conveyor Idlers

Unitrough Idlers have end supported wing rollers & comply with ISO & BS recommendations.

On such trough sets all rollers are interchangeable. Non-lead idler sets can be supplied on reversing conveyors.

3 Roll Troughing Idler Sets With Inverted Angle Transome

Belt Width Range: 400mm to 1600mm

Belt Width

(mm) |

Dimensions |

102mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

B+ (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Roller (Ref No.) |

Transome (Ref No.) |

| 400 |

160 |

75 |

130 |

640 |

200 |

MDA400/Π|

D16025 |

DA400/Π|

| 500 |

200 |

75 |

130 |

740 |

200 |

MDA500/Π|

D20025 |

DA500/Π|

| 600 |

240 |

75 |

130 |

840 |

200 |

MDA600/Π|

D24025 |

DA600/Π|

| 650 |

250 |

75 |

130 |

890 |

200 |

MDA650/Π|

D25025 |

DA650/Π|

| 750 |

295 |

75 |

130 |

990 |

200 |

MDA750/Π|

D29525 |

DA750/Π|

| 800 |

315 |

75 |

130 |

1040 |

200 |

MDA800/Π|

D31525 |

DA800/Π|

| 900 |

350 |

75 |

130 |

1140 |

200 |

MDA900/Π|

D35025 |

DA900/Π|

| 1000 |

380 |

75 |

130 |

1240 |

200 |

MDA1000/Π|

D38025 |

DA1000/Π|

| 1050 |

410 |

75 |

130 |

1300 |

200 |

MDA1050/Π|

D41025 |

DA1050/Π|

| 1200 |

465 |

100 |

170 |

1450 |

215 |

MDA1200/Π|

D46525 |

DA1200/Π|

| 1350 |

530 |

100 |

170 |

1600 |

215 |

MDA1350/Π|

D53025 |

DA1350/Π|

| 1400 |

530 |

100 |

170 |

1650 |

215 |

MDA1400/Π|

D53025 |

DA1400/Π|

| 1500 |

575 |

100 |

170 |

1800 |

215 |

MDA1500-S/Π|

D57525S |

DA1500/Π|

| 1600 |

600 |

100 |

170 |

1900 |

215 |

MDA1600-S/Π|

D60025S |

DA1600/Π|

Belt Width

(mm) |

Dimensions |

122mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

B+ (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Roller (Ref No.) |

Transome (Ref No.) |

| 400 |

160 |

75 |

130 |

640 |

222 |

MRA400/Π|

R16025 |

EA400/Π|

| 500 |

200 |

75 |

130 |

740 |

222 |

MRA500/Π|

R20025 |

EA500/Π|

| 600 |

240 |

75 |

130 |

840 |

222 |

MRA600/Π|

R24025 |

EA600/Π|

| 650 |

250 |

75 |

130 |

890 |

222 |

MRA650/Π|

R25025 |

EA650/Π|

| 750 |

295 |

75 |

130 |

990 |

222 |

MRA750/Π|

R29525 |

EA750/Π|

| 800 |

315 |

75 |

130 |

1040 |

222 |

MRA800/Π|

R31525 |

EA800/Π|

| 900 |

350 |

75 |

130 |

1140 |

222 |

MRA900/Π|

R35025 |

EA900/Π|

| 1000 |

380 |

75 |

130 |

1240 |

222 |

MRA1000/Π|

R38025 |

EA1000/Π|

| 1050 |

410 |

75 |

130 |

1300 |

222 |

MRA1050/Π|

R41025 |

EA1050/Π|

| 1200 |

465 |

100 |

170 |

1450 |

237 |

MRA1200/Π|

R46525 |

EA1200/Π|

| 1300 |

530 |

100 |

170 |

1600 |

237 |

MRA1350/Π|

R53025 |

EA1350/Π|

| 1400 |

530 |

100 |

170 |

1650 |

237 |

MRA1400/Π|

R53025 |

EA1400/Π|

| 1500 |

575 |

100 |

170 |

1800 |

237 |

MRA1500-S/Π|

R57525S |

EA1500/Π|

| 1600 |

600 |

100 |

170 |

1900 |

237 |

MRA1600-S/Π|

R60025S |

EA1600/Π|

Belt Width

(mm) |

Dimensions |

127mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

B+ (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Roller (Ref No.) |

Transome (Ref No.) |

| 400 |

160 |

75 |

130 |

640 |

225 |

MEA400/Π|

E16025 |

EA400/Π|

| 500 |

200 |

75 |

130 |

740 |

225 |

MEA500/Π|

E20025 |

EA500/Π|

| 600 |

240 |

75 |

130 |

840 |

225 |

MEA600/Π|

E24025 |

EA600/Π|

| 650 |

250 |

75 |

130 |

890 |

225 |

MEA650/Π|

E25025 |

EA650/Π|

| 750 |

295 |

75 |

130 |

990 |

225 |

MEA750/Π|

E29525 |

EEA750/Π|

| 800 |

315 |

75 |

130 |

1040 |

225 |

MEA800/Π|

E31525 |

EA800/Π|

| 900 |

350 |

75 |

130 |

1140 |

225 |

MEA900/Π|

E35025 |

EA900/Π|

| 1000 |

380 |

75 |

130 |

1240 |

225 |

MEA1000/Π|

E38025 |

EA1000/Π|

| 1050 |

410 |

75 |

130 |

1300 |

225 |

MEA1050/Π|

E41025 |

EA1050/Π|

| 1200 |

465 |

100 |

170 |

1450 |

240 |

MEA1200/Π|

E46525 |

EA1200/Π|

| 1300 |

530 |

100 |

170 |

1600 |

240 |

MEA1300/Π|

E53025 |

EA1300/Π|

| 1400 |

530 |

100 |

170 |

1650 |

240 |

MEA1400/Π|

E53025 |

EA1400/Π|

| 1500 |

575 |

100 |

170 |

1800 |

240 |

MEA1500/Π|

E57525S |

EA1500/Π|

| 1600 |

600 |

100 |

170 |

1900 |

240 |

MEA1600/Π|

E60025S |

EA1600/Π|

All roller lengths conform to BS and ISO Standards except 575

1. /Œ = Angle of side of rollers, 25º, 35º or 45º

2. Suffix -S after roller or transome set ref. indicates heavier duy rollers with stepped spindles (i.e. 27 dia. to 25 dia. at bearings)

3. Stepped spindles can also be offered for other sizes on request

3 Roll Impact Sets With Inverted Angle Transome

Belt Width Range: 400mm to 1600mm

Belt Width

mm) |

Dimensions |

108mm Diameter Impact Rollers |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Roller (Ref No.) |

Transome (Ref No.) |

| 400 |

160 |

75 |

640 |

200 |

MDIA400/Π|

UCI2108ST2-160 |

DIA400/Π|

| 500 |

200 |

75 |

740 |

200 |

MDIA500/Π|

UCI2108ST2-200 |

DIA500/Π|

| 600 |

240 |

75 |

840 |

200 |

MDIA600/Π|

UCI2108ST2-240 |

DIA600/Π|

| 650 |

250 |

75 |

890 |

200 |

MDIA650/Π|

UCI2108ST2-250 |

DIA650/Π|

| 750 |

295 |

75 |

990 |

200 |

MDIA750/Π|

UCI2108ST2-295 |

DIA750/Π|

| 800 |

315 |

75 |

1040 |

200 |

MDIA800/Π|

UCI2108ST2-315 |

DIA800/Π|

| 900 |

350 |

75 |

1140 |

200 |

MDIA900/Π|

UCI2108ST2-350 |

DIA900/Π|

| 1000 |

380 |

75 |

1240 |

200 |

MDIA1000/Π|

UCI2108ST2-380 |

DIA1000/Π|

| 1050 |

410 |

75 |

1300 |

200 |

MDIA1050/Π|

UCI2108ST2-410 |

DIA1050/Π|

| 1200 |

465 |

100 |

1450 |

215 |

MDIA1200/Π|

UCI2108ST2-465 |

DIA1200/Π|

| 1350 |

530 |

100 |

1600 |

215 |

MDIA1350/Π|

UCI2108ST2-530 |

DIA1350/Π|

| 1400 |

530 |

100 |

1650 |

215 |

MDIA1400/Π|

UCI2108ST2-530 |

DIA1400/Π|

| 1500 |

575 |

100 |

1800 |

215 |

MDIA1500-S/Π|

UCI2108ST2-575 |

DIA1500/Π|

| 1600 |

600 |

100 |

1900 |

215 |

MDIA1600-S/Π|

UCI2108ST2-600 |

DIA1600/Π|

Belt Width

mm) |

Dimensions |

133mm Diameter Impact Rollers |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Roller (Ref No.) |

Transome (Ref No.) |

| 400 |

160 |

75 |

640 |

225 |

MEIA400/Π|

UCI2133ST2-160 |

EIA400/Π|

| 500 |

200 |

75 |

740 |

225 |

MEIA500/Π|

UCI2133ST2-200 |

EIA500/Π|

| 600 |

240 |

75 |

840 |

225 |

MEIA600/Π|

UCI2133ST2-240 |

EIA600/Π|

| 650 |

250 |

75 |

890 |

225 |

MEIA650/Π|

UCI2133ST2-250 |

EIA650/Π|

| 750 |

295 |

75 |

990 |

225 |

MEIA750/Π|

UCI2133ST2-295 |

EIA750/Π|

| 800 |

315 |

75 |

1040 |

225 |

MEIA800/Π|

UCI2133ST2-315 |

EIA800/Π|

| 900 |

350 |

75 |

1140 |

225 |

MEIA900/Π|

UCI2133ST2-350 |

EIA900/Π|

| 1000 |

380 |

75 |

1240 |

225 |

MEIA1000/Π|

UCI2133ST2-380 |

EIA1000/Π|

| 1050 |

410 |

75 |

1300 |

225 |

MEIA1050/Π|

UCI2133ST2-410 |

EIA1050/Π|

| 1200 |

465 |

100 |

1450 |

240 |

MEIA1200/Π|

UCI2133ST2-465 |

EIA1200/Π|

| 1350 |

530 |

100 |

1600 |

240 |

MEIA1350/Π|

UCI2133ST2-530 |

EIA1350/Π|

| 1400 |

530 |

100 |

1650 |

240 |

MEIA1400/Π|

UCI2133ST2-530 |

EIA1400/Π|

| 1500 |

575 |

100 |

1800 |

240 |

MEIA1500/Π|

UCI2133ST2-575 |

EIA1500/Π|

| 1600 |

600 |

100 |

1900 |

240 |

MEIA1600/Π|

UCI2133ST2-600 |

EIA1600/Π|

1. /Œ = Angle of side of rollers, 25º, 35 or 45

2. Suffix -S after roller or transome set ref. indicates heavier duy rollers with stepped spindles (i.e. 27 dia. to 25 dia. at bearings)

3. Stepped spindles can also be offered for other sizes on request

3 Roll Picking Idler Sets With Inverted Angle Transome

Belt Width Range: 750mm to 1600mm

Belt Width

(mm) |

Dimensions |

102mm Diameter Picking Idler Set |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Centre Roller (Ref No.) |

Side Roller (Ref No.) |

Transome (Ref No.) |

| 750 |

450 |

200* |

990* |

200* |

MDAP750/Π|

D45025 |

D20025 |

DAP750/Π|

| 800 |

500* |

200* |

1040* |

200* |

MDAP800/Π|

D50025 |

D20025 |

DAP800/Π|

| 900 |

600* |

200* |

1140* |

200* |

MDAP900/Π|

D60025 |

D20025 |

DAP900/Π|

| 1000 |

700* |

200* |

1240* |

200* |

MDAP1000/Π|

D70025 |

D20025 |

DAP1000/Π|

| 1050 |

760 |

200* |

1300* |

200* |

MDAP1050/Π|

D76025 |

D20025 |

DAP1050/Π|

| 1200 |

910 |

200* |

1450* |

215* |

MDAP1200/Π|

D91025 |

D20025 |

DAP1200Π|

| 1350 |

1060 |

200* |

1600 |

215* |

MDAP1350/Π|

D106025 |

D20025 |

DAP1350/Π|

| 1400 |

1110 |

200* |

1650 |

215* |

MDAP1400/Π|

D111025 |

D20025 |

DAP1400/Π|

| 1500 |

1260 |

200* |

1800 |

215* |

MDAP1500/Π|

D126025 |

D20025 |

DAP1500/Π|

| 1600 |

1360 |

200* |

1900* |

215* |

MDAP1600/Π|

D136025 |

D20025 |

DAP1600/Π|

Belt Width

(mm) |

Dimensions |

127mm Diameter Picking Idler Set |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

Transome Sets (Ref No.) |

Centre Roller (Ref No.) |

Side Roller (Ref No.) |

Transome (Ref No.) |

| 750 |

450 |

200* |

990* |

225* |

MEAP750/Π|

E45025 |

E20025 |

EAP750/Π|

| 800 |

500* |

200* |

1040* |

225* |

MEAP800/Π|

E50025 |

E20025 |

EAP800/Π|

| 900 |

600* |

200* |

1140* |

225* |

MEAP900/Π|

E60025 |

E20025 |

EAP900/Π|

| 1000 |

700* |

200* |

1240* |

225* |

MEAP1000/Π|

E70025 |

E20025 |

EAP1000/Π|

| 1050 |

760 |

200* |

1300* |

225* |

MEAP1050/Π|

E76025 |

E20025 |

EAP1050/Π|

| 1200 |

910 |

200* |

1450* |

225* |

MEAP1200/Π|

E91025 |

E20025 |

EAP1200/Π|

| 1350 |

1060 |

200* |

1600 |

225* |

MEAP1350/Π|

E106025 |

E20025 |

EAP1350/Π|

| 1400 |

1110 |

200* |

1650 |

225* |

MEAP1400/Π|

E111025 |

E20025 |

EAP1400/Π|

| 1500 |

1260 |

200* |

1800 |

225* |

MEAP1500/Π|

E126025 |

E20025 |

EAP1500/Π|

| 1600 |

1360 |

200* |

1900* |

225* |

MEAP1600/Π|

E136025 |

E20025 |

EAP1600/Π|

1. *Dimensions marked with an astrik conform to BS and ISO Standards

2. /Œ = Angle of side of rollers, 25º, 35º or 45º

Return Idlers

Belt Width Range: 400mm to 1600mm

Belt Width

(mm) |

Dimensions A (mm) |

102mm Dia. (Ref No.) |

127mm Dia. (Ref. No.) |

121mm Dia. Roller

with 10mm Thick Rubber Covering (Ref. No.) |

| 400 |

500* |

MDP400 |

MEP400 |

MRP400 |

| 500 |

600* |

MDP500 |

MEP500 |

MRP500 |

| 600 |

700* |

MDP600 |

MEP600 |

MRP600 |

| 650 |

750* |

MDP650 |

MEP650 |

MRP650 |

| 750 |

900* |

MDP750 |

MEP750 |

MRP750 |

| 800 |

950* |

MDP800 |

MEP800 |

MRP800 |

| 900 |

1050* |

MDP900 |

MEP900 |

MRP900 |

| 1000 |

1150* |

MDP1000 |

MEP1000 |

MRP1000 |

| 1050 |

1200* |

MDP1050 |

MEP1050 |

MRP1050 |

| 1200 |

1350* |

MDP1200 |

MEP1200 |

MRP1200 |

| 1350 |

1500* |

MDP1350-S |

MEP1350-S |

MRP1350-S |

| 1400 |

1550 |

MDP1400-S |

MEP1400-S |

MRP1400-S |

| 1500 |

1700 |

MDP1500-S |

MEP1500-S |

MRP1500-S |

| 1600 |

1800* |

MDP1600-S |

MEP1600-S |

MRP1600-S |

1. *Dimensions marked with an astrik conform to BS and ISO Standards

2. Suffix -S after roller ref. indicates heavier duty rollers with stepped spindles (i.ei 27 dia. to 25 dia. at bearings)

Disc Return Idlers

Belt Width Range: 400mm to 1600mm

Belt Width

(mm) |

Dimensions |

152mm Dia. Discs (Ref No.) |

191mm Dia. Discs (Ref No.) |

| A (mm) |

B (No.of Pitches) |

C (mm) |

| 400 |

500* |

2 |

122 |

MBP6D400 |

MCP7D400 |

| 500 |

600* |

3 |

122 |

MBP6D500 |

MCP7D500 |

| 600 |

700* |

3 |

122 |

MBP6D600 |

MCP7D600 |

| 650 |

750* |

4 |

122 |

MBP6D650 |

MCP7D650 |

| 750 |

900* |

4 |

147 |

MBP6D750 |

MCP7D750 |

| 800 |

950* |

4 |

147 |

MBP6D800 |

MCP7D800 |

| 900 |

1050* |

5 |

147 |

MBP6D900 |

MCP7D900 |

| 1000 |

1150* |

6 |

147 |

MBP6D1000 |

MCP7D1000 |

| 1050 |

1200* |

6 |

147 |

MBP6D1050 |

MCP7D1050 |

| 1200 |

1350* |

7 |

147 |

MBP6D1200 |

MCP7D1200 |

| 1350 |

1500* |

8 |

147 |

MBP6D1350 |

MCP7D1350 |

| 1400 |

1550 |

8 |

147 |

MBP6D1400-S |

MCP7D1400-S |

| 1500 |

1700 |

9 |

172 |

MBP6D1500-S |

MCP7D1500-S |

| 1600 |

1800* |

10 |

172 |

MBP6D1600-S |

MCP7D1600-S |

1. *Dimensions marked with an astrik conform to BS and ISO Standards

2. Suffix -S after roller ref. indicates heavier duty rollers with stepped spindles (i.ei 27 dia. to 25 dia. at bearings)

3 Roll Intertrough-type Troughing Idler Sets

Belt Width Range: 600mm to 1200mm

Belt Width

(mm) |

Dimensions |

102mm Diameter Troughing Idlers |

| A (mm) |

B (mm) |

Transome Sets (Ref. No.) |

Centre Roller (Ref No.) |

Sider Roller & Bracket (Ref No.) All Angles |

| 600 |

305 |

406 |

IT600/Π|

L314CR |

IT220SR#/Π|

| 650 |

305 |

406 |

IT650/Π|

L314CR |

IT220SR#/Π|

| 750 |

379 |

480 |

IT750/Π|

L388CR |

IT220SR#/Π|

| 800 |

379 |

480 |

IT800/Π|

L388CR |

IT220SR#/Π|

| 900 |

529 |

630 |

IT900/Π|

L538CR |

IT220SR#/Π|

| 1000 |

639 |

740 |

IT1000/Π|

L648CR |

IT220SR#/Π|

| 1200 |

863 |

1008 |

IT1200/Π|

L916CR |

IT220SR#/Π|

1. /Œ = Angle of side rollers with bracket 20º, 30º, 40º, 50º or 60º

2. # = RH for Right Hand side or LH for Left Hand side

Intertrough-type Return Idlers

Belt Width Range: 600mm to 1500mm

Belt Width

(mm) |

Dimensions |

Ref No. |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

| 600 |

710 |

840 |

20 |

65 |

ITR710 |

| 650 |

710 |

840 |

20 |

65 |

ITR710 |

| 750 |

850 |

980 |

20 |

65 |

ITR850 |

| 800 |

895 |

1025 |

20 |

65 |

ITR895 |

| 900 |

1019 |

1145 |

20 |

63 |

ITR1019 |

| 1000 |

1119 |

1280 |

20 |

80.5 |

ITR1119 |

| 1050 |

1190 |

1320 |

20 |

65 |

ITR1190 |

| 1200 |

1319 |

1485 |

20 |

83 |

ITR1319 |

| 1500 |

1559 |

1700 |

25 |

70.5 |

ITR1559 |

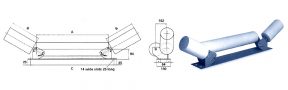

Field Conveyors

Standard Field Conveyor Systems

An alternative to standard conveying systems, Field Conveyors are an immediate conveying solution for the most rugged of environments.

Designed for rapid & easy installation in a fraction of the time it would take to install a conventional conveyor of similar size.

The conveyor sets are available with a fixed troughing angle of 30°, 35° or with variable spring loaded troughing angles.

The sets are interchangeable with other variable trough structures of similar design.

Trough Idlers

Belt Width Range: 105mm to 1200mm

| Belt Width (mm) |

Dimensions |

| A Stringer Ctrs (mm) |

B 102mm Dia. Roller |

B 127mm Dia. Roller |

C Roller Length (mm) |

D (mm) |

E (mm) |

| 500 |

765 |

102 |

127 |

190 |

47 |

57 |

| 600 |

865 |

102 |

127 |

224 |

66 |

61 |

| 650 |

916 |

102 |

127 |

240 |

76 |

65 |

| 750 |

1016 |

102 |

127 |

280 |

93 |

60 |

| 800 |

1067 |

102 |

127 |

295 |

103 |

66 |

| 900 |

1168 |

102 |

127 |

330 |

122 |

69 |

| 1000 |

1270 |

102 |

127 |

360 |

143 |

80 |

| 1050 |

1321 |

102 |

127 |

380 |

152 |

78 |

| 1200 |

1473 |

102 |

127 |

432 |

182 |

87 |

Return Idlers

Belt Width Range: 500mm to 1200mm

| Belt Width (mm) |

Dimensions |

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

F (mm) |

H (mm) |

K (mm) |

| 500 |

102 or 127 |

600 |

48 |

25 dia. |

14 A/F |

25 |

14 |

| 600 |

102 or 127 |

700 |

48 |

25 dia. |

14 A/F |

25 |

14 |

| 650 |

102 or 127 |

750 |

48 |

25 dia. |

14 A/F |

25 |

14 |

| 750 |

102 or 127 |

900 |

48 |

25 dia. |

14 A/F |

25 |

14 |

| 800 |

102 or 127 |

950 |

48 |

25 dia. |

14 A/F |

25 |

14 |

| 900 |

102 or 127 |

1050 |

49 |

25 dia. |

14 A/F |

25 |

14 |

| 1000 |

102 or 127 |

1175 |

50 |

25 dia. |

14 A/F |

25 |

14 |

| 1050 |

102 or 127 |

1210 |

50 |

25 dia. |

14 A/F |

25 |

14 |

| 1200 |

102 or 127 |

1360 |

51 |

25 dia. |

14 A/F |

25 |

14 |

Standard Field Conveyor

Belt Width Range: 600mm to 1200mm

| Belt Width (mm) |

Dimensions |

102mm Dia. Rollers |

127mm Dia. Rollers |

| A (mm) |

B (mm) |

C (mm) |

E (mm) |

F (mm) |

| 600 |

3048 |

865 |

606 |

224 |

700 |

540 |

- |

| 650 |

3048 |

916 |

609 |

240 |

750 |

533 |

- |

| 750 |

3048 |

1016 |

699 |

280 |

900 |

606 |

618 |

| 800 |

3048 |

1067 |

702 |

295 |

950 |

599 |

611 |

| 900 |

2743 |

1168 |

705 |

330 |

1050 |

583 |

595 |

| 1000 |

2743 |

1270 |

712 |

360 |

1175 |

569 |

581 |

| 1050 |

2743 |

1321 |

749 |

380 |

1210 |

597 |

610 |

| 1200 |

2743 |

1473 |

816 |

430 |

1360 |

- |

646 |

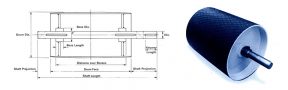

Conveyor Drums

Selection of the correct drum & shaft is essential to both the satisfactory operation of a conveyor & for belt life.

Please remember that our technical assistance is always available to you without charge.

Drums are fabricated from steel shells with closed steel end plates, incorporating welded bosses.

All welding is continuous for maximum strength.

Conveyor Drum With Welded Shaft

Belt Width Range: 25mm to 85mm

| Belt Width (mm) |

Metric Bore (mm) |

Imperial Bore (mm) |

Boss Dia. 9mm) |

Boss Lgth (mm) |

Metric Bore (mm) |

Imperial Bore (mm) |

Boss Dia. (mm) |

Boss Lgth (mm) |

| 25 |

25 |

1.00 |

40 |

15 |

90-95 |

3.50-3.75 |

140 |

30 |

| 30 |

30 |

1.25 |

45 |

20 |

100 |

4.00 |

150 |

40 |

| 35 |

35 |

1.375 |

60 |

20 |

105-110 |

4.25 |

160 |

40 |

| 40 |

40 |

1.5 |

60 |

20 |

115 |

4.50 |

180 |

40 |

| 45 |

45 |

1.75 |

70 |

25 |

120 |

4.75 |

180 |

40 |

| 50 |

50 |

2.00 |

75 |

25 |

125-130 |

5.00 |

200 |

40 |

| 55 |

55 |

2.25 |

85 |

25 |

135-140 |

5.50 |

210 |

50 |

| 60 |

60 |

2.375 |

90 |

25 |

150 |

6.00 |

230 |

50 |

| 65 |

65 |

2.5 |

100 |

30 |

160 |

6.50 |

240 |

50 |

| 70-75 |

70-75 |

2.75-3.00 |

115 |

30 |

170 |

6.75 |

260 |

50 |

| 80-85 |

80-85 |

3.25 |

130 |

30 |

180 |

7.00 |

270 |

50 |

Conveyor Drums With Keyed Shaft

Belt Width Range: 25mm to 80mm

| Belt Width (mm) |

Bore (mm) |

Keyway (mm) |

Bore (ins) |

Keyway (ins) |

Boss Dia. (mm) |

Boss Lgth. (mm) |

| 25 |

25 |

8 x 2.4 |

1.00 |

0.25 x 0.09 |

40 |

25 |

| 30 |

30 |

8 x 2.4 |

1.25 |

0.31 x 0.09 |

50 |

30 |

| 35 |

35 |

10 x 2.4 |

1.375 |

0.37 x 0.09 |

60 |

35 |

| 40 |

40 |

12 x 2.4 |

1.50 |

0.37 x 0.09 |

65 |

40 |

| 45 |

45 |

14 x 2.9 |

1.75 |

0.43 x 0.12 |

75 |

45 |

| 50 |

50 |

14 x 2.9 |

20.. |

0.50 x 0.12 |

80 |

50 |

| 55 |

55 |

16 x 3.4 |

2.25 |

0.62 x 0.16 |

90 |

55 |

| 60 |

60 |

18 x 3.4 |

2.375 |

0.62 x 0.16 |

100 |

60 |

| 65 |

65 |

18 x 3.4 |

2.50 |

0.62 x 0.16 |

110 |

65 |

| 70 |

70 |

20 x 3.9 |

2.75 |

0.75 x 0.19 |

120 |

70 |

| 75 |

75 |

20 x 3.9 |

3.00 |

0.75 x 0.19 |

130 |

75 |

| 80 |

80 |

22 x 4.4 |

3.25 |

0.87 x 0.24 |

130 |

80 |

English (UK)

English (UK)  Русский (RU)

Русский (RU)