Self Contained Crushing Plants

Mobile Crushing & Screening Plants with Integrated Screens

Parker CrushRanger models are two stage, closed-circuit arrangements that provide three product sizes at outputs of up to 100tph. The Hunter simply comprises a crusher with power unit and optional rotary screen mounted below the crusher.

These plants are particularly suitable for contractors working in remote locations.

CrushRanger, Two Stage Crushers

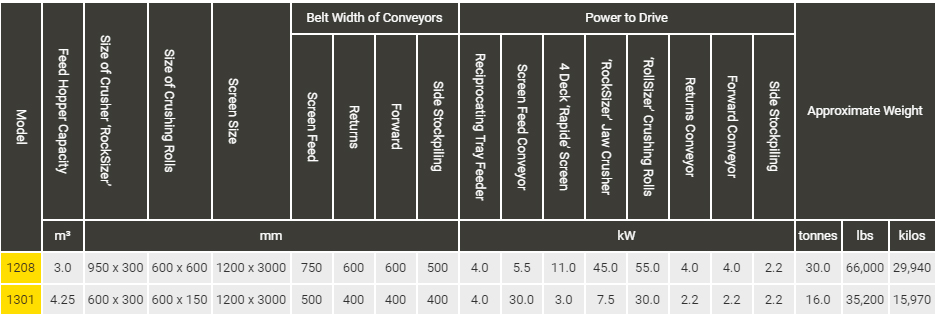

CrushRanger 1208

The 1208 combines a feed hopper and feeder, 900 x 600mm RockSizer jaw crusher, 610 x 610mm RollSizer rolls crusher, 1.2m wide x 3m long four deck inclined vibrating screen with feed and returns conveyors all mounted on the same semi-trailer chassis. This provides a compact and highly mobile solution to any operator needing medium quantities of quality sized aggregates in remote or rural locations.

The reciprocating tray feeder and feed hopper supplies material to the main feed conveyor which is discharged onto the four-deck Rapide vibrating screen. Rejects from the two top decks are crushed by the RockSizer jaw crusher and RollSizer crushing rolls and returned to the main feed conveyor for further screening. The two lower screen decks produce three graded products. Plant capacity when producing to minus 40mm is up to 100 tph with crushed rock or up to 200 tph when handling sand and gravel.

- Feed Hopper

- Reciprocating Tray Feeder

- Screen Feed Conveyor

- Rapide Screen

- Roll-Sizer Crushing Rolls

- RockSizer Jaw Crusher

- Forward Product Conveyor

- Side Product Conveyor

- Returns Conveyor

- Ringovator

| CrushRanger 1208 Approx Hourly Capacities* | ||||

| Material | < 12mm | < 25mm | < 40mm | |

| TPH | ||||

| Sand & Gravel | 80-100 | 100-140 | 180-220 | |

| Crushed Rock | 60-65 | 65-70 | 85-100 | |

CrushRanger 1301

With a feed hopper and feeder, 600 x 300mm RockSizer jaw crusher, 600 x 300mm StoneSizer granulator crusher, 3m wide x 1.2m long three deck inclined vibrating screen, and feed and returns conveyors all mounted on the same semi-trailer chassis, the CrushRanger Model 1301 provides a compact and highly mobile solution to any operator needing medium quantities of quality sized aggregates in remote or rural locations.

In standard form the model 1301 can deliver three sizes of graded products at rates of up to 50 tph when producing to minus 40mm, with the option of four products using a split bottom deck arrangement and additional stockpile conveyor if specified at time of order.

- Feed Hopper

- Vibrating Feeder

- RockSizer Jaw Crusher

- Screen Feed Conveyor

- Rapide Screen

- StoneSizer Jaw Crusher

- Forward Product Conveyor

- Side Product Conveyor Chute

- Returns Conveyor

- Control Panel

| CrushRanger 1301 Approx Hourly Capacities* | ||||

| Max Feed Size m³ | < 12mm | < 25mm | < 40mm | |

| TPH | ||||

| 280 | 20-30 | 25-40 | 30-50 | |

*NOTE: Capacities quoted are intended as a guideline only, and are based on a clean, dry graded continuous feed material (weighing 1600kg/m³ (100lb/ft³) and a S.G of 2.7 average), which will readily enter the crusher feed opening without obstruction, with 100% greater than the jaw setting and 25% less than twice the jaw setting.

Actual capacities can vary considerably from those given, due to the following application and operational factors: 1) MATERIAL - Friability & Toughness, 2) FEED CONDITIONS - Grading of feed size (Compliance with Euro STD). 3) INSTALLATION - Method of feeding, Removal of under size. [Operation at settings outside those stated should be referred to the works].

Hunter Series

Standard Jaw crushers from the well proven ‘RockSizer’, ‘StoneSizer’ and ‘V’ type ranges are mounted on a robust fabricated chassis with a diesel engine or electric motor to make up the ‘Hunter’ rock crushing outfit. These simple, self contained plants may be supplied as mobile, portable or fixed units.

Drive is by either diesel engine or electric motor and powers the crusher via vee belt. Production capacity can be achieved of up to 65tph and handle material of up to 280mm.

* Optional equipment

| Size And Type Of Crusher | Max Size Of Feed | Max Jaw Setting (mm) | MIN JAW SETTING (mm) | Power (kW) |

| 400 x 175 V-TYPE* | 155 | 40 | 20 | 15 |

| 400 x 250 V-TYPE* | 230 | 65 | 30 | 15 |

| 600 X 150 StoneSizer | 125 | 40 | 20 | 30 |

| 600 X 300 RockSizer | 280 | 75 | 30 | 30 |

* A conversion kit is available to change a 400 x 250 crusher into a 400 x 175 crusher.

| Approximate Hourly Capacities At 100% Crush | ||||||

| Size Of Crusher | 20mm Jaw Setting |

30mm Jaw Setting |

40mm Jaw Setting |

50mm Jaw Setting |

65mm Jaw Setting |

75mm Jaw Setting |

| 400 x 175 | 5 - 9tph | 7 - 11tph | 8 - 12tph | |||

| 400 x 250 | 7 - 14tph | 8 - 15tph | 10 - 20tph | 15 - 25tph | ||

| 600 X 150 | 14 - 18tph | 22 - 26tph | 25 - 30tph | |||

| 600 X 300 | 22 - 30tph | 25 - 35tph | 30 - 45tph | 35 - 55tph | 35 - 65tph | |

*NOTE: Capacities quoted are intended as a guideline only, and are based on a clean, dry graded continuous feed material (weighing 1600kg/m3 (100lb/ft3) and a S.G of 2.7 average), which will readily enter the crusher feed opening without obstruction. Actual capacities can vary considerably from those given, due to the following application and operational factors: 1) MATERIAL - Friability & Toughness, 2) FEED CONDITIONS - Grading of feed size (Compliance with Euro STD). 3) INSTALLATION - Method of feeding, Removal of under size. [Operation at settings outside those stated should be referred to the works]

English (UK)

English (UK)  Русский (RU)

Русский (RU)