Recycling Crushing Plants

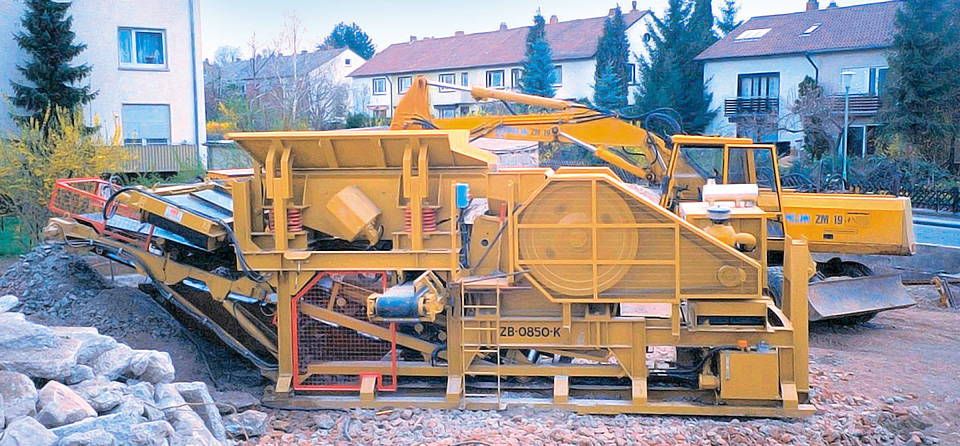

Crushing Plants for recycling applications in urban environments

The Parker RM and RJ models are ideal for recycling, demolition and volume reduction projects in constrained inner city environments.

The RM0745 is arranged for transport using a standard hook lift truck, whereas the RJ0850 uses integral swivelling hydraulic jacks to raise the unit from ground level and enable a flat bed trailer to reverse under for transport.

Drive is from a diesel hydraulic power-pack complete with sound attenuation for use on sites in noise sensitive areas.

Both models are fed by a vibrating grizzly and are capable of producing up to 140 tph depending on the feed material and closed side setting used.

Each plant is easy to operate and all service work can be carried out from the ground.

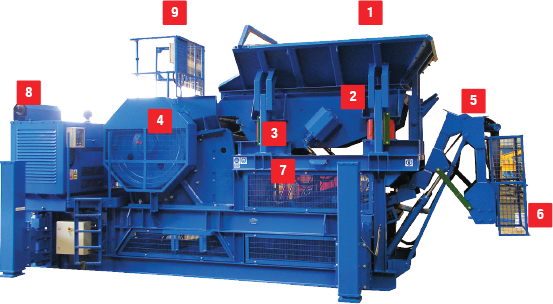

RockRanger RJ0850

The ‘RockRanger RJ’ is a fully transportable primary crushing plant complete with a Parker ‘Rocksizer’ single toggle Jaw crusher. The under frame is carried on bottom members designed to distribute ground loading, and is complete with a set of four hydraulic jack legs operated from the main plant hydraulic system to raise the crusher up for positioning on a suitable trailer unit.

Built around a strong straight beam chassis with standard supports for feed section, jaw crusher, power unit and conveyor frame. The ‘RockRanger RJ’ is a high-capacity, extremely mobile crushing unit suitable for urban recycling and demolition projects.

- Feed Hopper - 3.5m³ capacity

- Vibrating Grizzly Feeder: 0.9m x 2.8m

- By-pass Chute

- RockSizer Jaw Crusher - 800 x 500mm

- Optional Magnetic Separator - 570gauss @ 200mm

- Product Conveyor - discharge height 2.05mm

- Side Dirt Conveyor - 450mm wide, 1.32m discharge height

- Power Unit - CAT 3116 90kW

- Control Station

| Weight (tonnes) | Capacity (tph) | Max Feed Size (mm) | Crusher lift-up Clearance | Travelling Dimensions (mm) | |||

| 50 | 125 | Length | Width | Height | |||

| 25.5 | 50/65 | 105/140 | 455 | 1150 | 7400 | 2500 | 2700 |

| Working Dimensions (mm) | |||||||

| Length | Width | Height | |||||

| 8800 | 3200 | 3350 | |||||

Options

- Side discharge conveyor

- Over-band magnet

- Hydraulic clutch release

- Dust supression

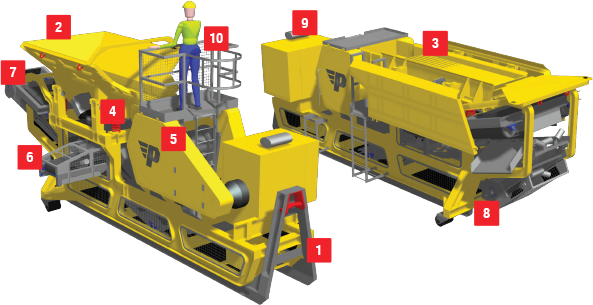

RockRanger RM0745

The ‘RockRanger’ RM is a fully transportable hook-lift type primary crushing plant complete with a Parker ‘Rocksizer’ single toggle Jaw crusher. The under-frame members are designed to the universal industry standard for hook lift frames [DIN or CHEM Standard] and when off-loaded distributes ground loadings.

The straight beam design chassis incorporates access and maintenance platforms to the engine and crusher and platforms to one side of the crusher feed chute. The ‘RockRanger’ RM is a high-capacity, extremely versatile mobile crushing unit suitable for urban recycling and demolition projects.

- Underframe & Hook Arrangement

- Feed Hopper - 3.4m³ capacity

- Vibrating Grizzly Feeder - 0.8 x 2.7m

- By-pass Chute

- RockSizer Jaw Crusher - 700 x 450mm

- Side Conveyor - 450mm wide, 1.36m discharge height

- Forward Product Conveyor - 1.91m discharge height

- Magnetic Separator

- Power Unit - Caterpillar 3054T 70kW

- Operators Platform

| Weight (tonnes) | Capacity (tph) | Max Feed Size (mm) | Travelling Dimensions (mm) | ||

| Length | Width | Height | |||

| 15 | 140 | 410 | 7320 | 2450 | 2650 |

| Working Dimensions (mm) | |||||

| Length | Width | Height | |||

| 8550 | 2860 | 3675 | |||

- By-pass Chute

- Magnetic Separator

- Dust Suppression

- Dirt Conveyor

- Diesel Hydraulic, Electric Hydraulic or Electric Power

English (UK)

English (UK)  Русский (RU)

Русский (RU)