SuperRoadMix

Mobile Asphalt Plants

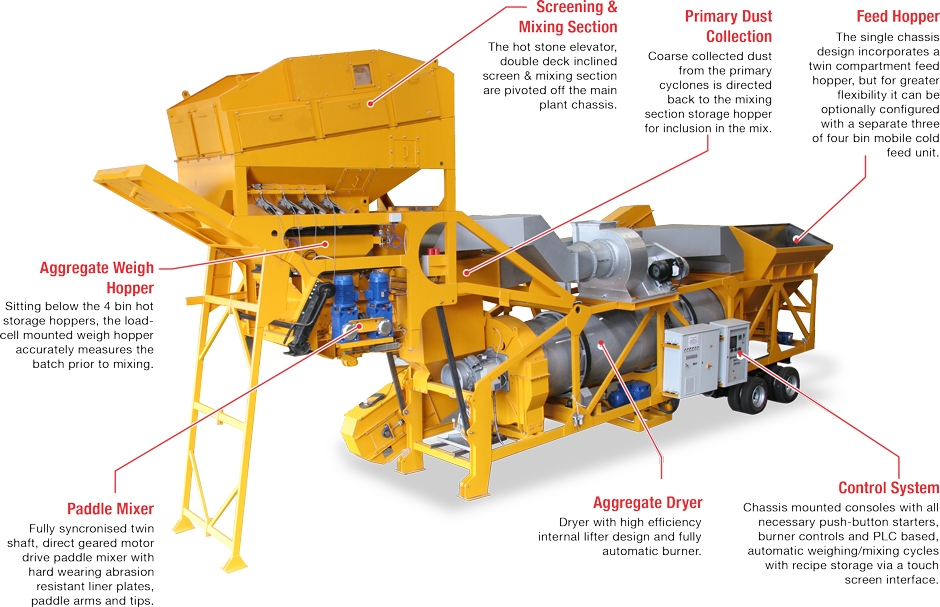

Compact, highly mobile/portable, wheeled, single chassis asphalt batch mix plants.

SuperRoadMix is available with capacities of 30, 60 or 90 TPH.

Mounted on a single chassis are all the components necessary to repeatedly and reliably deliver upto 90 t/h of high quality asphalt. Comprising a twin compartment feed hopper, dryer, automatic burner, hot stone elevator, inclined vibrating screen, load- cell weighing system, twin-shaft paddle mixer, primary dust cyclones and full PLC controls.

Features

Unique single chasis design

All the necessary components are mounted on a single chassis: Twin compartment feed hopper, dryer, automatic burner, hot stone elevator, inclined vibrating screen, loadcell weighing system, twin-shaft paddle mixer, primary dust cyclones and full PLC controls.

Fully mobile road towable

The plant is mounted on a fully mobile chassis with pneumatic tyred running gear and fifth wheel towing attachment for towing vehicle.

Fast one day on-site set-up & relocation

The screening and mixing section of the plant and the hot stone elevator are pivoted off the main plant chassis and can each be raised manually with no cranes necessary to their operating positions within minutes.

Minimum fundations required

Minimal foundations are required for installation as each unit has landing legs with support bases to ensure adequate stability.

Chasis mounted consoles

Chassis mounted consoles with all necessary push-button starters,burner controls and PLC based, automatic weighing/mixing cycles with recipe storage via a touch screen interface. Alternatively the console can be mounted in an optional control cabin.

Inverter controled exhaust fan

An inverter maintains infinitely variable speed control over the exhaust fan thereby controlling the airflow through the dryer, resulting in greater fuel economy and reduced plant energy costs.

Optional separate cold feed

For greater control over aggregate feeds the plant can be used with a separate three or four bin mobile cold feed unit with variable speed control on each feeder.

Optional control cabin

The control consoles can be mounted in an optional separate cabin.

Optional secondary dust filter

For projects in environmentally sensitive locations, the SuperRoadMix can be combined with a mobile or fixed bag filter to contain emission levels to less than 20mg/m³. Collected dust is screwed directly to the mixing section filler weigh hopper on the plant, for reintroduction into the mix.

Optional bitumen tanks

Fully mobile or transportable, hot oil or electrically heated bitumen tanks and pumping systems are available to compliment the plant.

Options

- Separate three or four bin cold feed unit

- Control Cabin

- Mobile or static secondary dust filter

- Bitumen Tanks

Specifications

| Units | SRM30 | SRM60 | SRM90 | |

| Cold Feed | ||||

| Hopper Capacity (heaped) | m³ | 5.0 | 7.0 | 9.0 |

| Hopper Loading Width | m | 2.0 | 2.5 | 3.0 |

| Belt Feeder Length | m | 1.8 | 2.5 | 3.2 |

| Belt Width | mm | 500 | 500 | 500 |

| Belt Feeder Drive | kW | 4 | 4 | 4 |

| Aggregate Dryer | ||||

| Dryer Drum Diameter | m | 1.2 | 1.4 | 1.6 |

| Dryer Drum Length | m | 4.5 | 5.5 | 6.5 |

| Dryer Drive | kW | 11.0 | 15.0 | 22.0 |

| Dryer Capacity | t/h | 30 | 60 | 95 |

| Dryer Air Volume | m³/h | 11,650 | 16,000 | 29,800 |

| Exhaust Fan Drive | kW | 18.5 | 22 | 30 |

| Hot Stone Elevator, Screen & Mixing Section | ||||

| Elevator Capacity | t/h | 35 | 70 | 95 |

| Drive | kW | 4.0 | 5.5 | 7.5 |

| Screen Decks | No. | 2 | 2 | 2 |

| Screen Length | m | 2.0 | 3.0 | 3.0 |

| Screen Width | m | 1.0 | 1.2 | 1.5 |

| Screen Drive | kW | 4.0 | 5.5 | 7.5 |

| Hot Storage Capacity | t | 3.2 | 6.4 | 9.6 |

| Hot Storage Bins | No. | 4 | 4 | 4 |

| Aggregate Weigh Hopper Capacity | kg | 400 | 750 | 1200 |

| Bitumen Weigh Hopper Capacity | kg | 60 | 120 | 180 |

| Filler Weigh Hopper Capacity | kg | 75 | 150 | 240 |

| Paddle Mixer Capacity | kg | 400 | 800 | 1200 |

| Paddle Mixer Drive | kW | 2 x 5.5 | 2 x 7.5 | 2 x 11 |

English (UK)

English (UK)  Русский (RU)

Русский (RU)